My first priorities are sound and playability. I work a little bit different from most guitar makers in that if there is a “feature” I believe improves the functionality or performance of an instrument, then it just becomes “standard”. Considering the time and effort involved in the crafting of a concert instrument I feel like I owe it to myself to build the very best instrument I can.

Adjustable Neck:

Commonly seen on instruments from the 19th century, the construction of an adjustable neck is not a new concept. I’ve embraced the idea based on my experience with the needs of concert players. Mainly, it's the requirement for the ultimate in sound, sensitivity and responsiveness from an instrument paired with the ability to optimize the action to compensate for different performance needs and humidity variations. On my guitars a player can adjust the neck to their ideal playability in matter of moments.

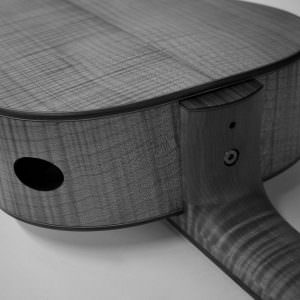

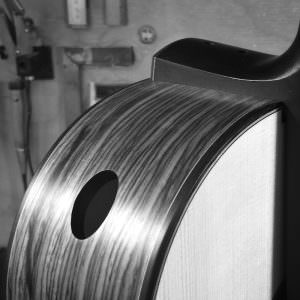

Structured Sides:

The “output” of a guitar is directly related to how much of (and how efficiently) the top is being "used”. Minimizing losses to the system and ensuring that as much of the potential energy possible is contributing to the production of sound is fundamental. Increasing the stiffness of the perimeter allows me to transfer an element of the structural load of the top into the sides and establishes a dramatic reduction in inherent stress. Freeing the top from that stress allows me to simplify the intention of its structure to maximize the potential for sound production. In many ways the weight of the perimeter matters just as much as the stiffness. When you examine the node lines of the primary resonant frequency of the top of a typical guitar they are (usually) somewhat “inboard" of the perimeter. Adding mass to the sides shifts the node lines closer to the perimeter (i.e. more of the top working in phase) demonstrating the reduction in the movement of the guitar body and an increase in the movement of the top. More movement directly equates to more sound.

Hexagonal Bracing:

Few elements of construction have fascinated me more than bracing. I have built with or tested hundreds of patterns. Traditional (and non-traditional) fan patterns, lattice patterns, radial patterns, ladder patterns, and a multitude of other variants. I tend to view braces as not only a structural component but also as a system to influence movement(s). “How” the top moves is an incredibly critical component to the quality of the instrument. Balancing those movements and controlling which frequencies they present at, contribute to the voice and overall efficiency of the soundboard. Several years back I devised a bracing pattern based on the fact that the triangle is the most basic self stabilizing polygon. Six equilateral triangles around a vertex is one of the only entirely symmetrical/stable least-effort structural systems in nature. The evolution of my initial idea has developed (currently) into a single hexagon supporting the bridge area that is "tethered" to the perimeter. It’s a beautifuly simple distribution of stiffness that provides an impressive monopole mobility (here again, more movement equates to more sound) and gives me the ability to manipulate the top in ways that I really like. The resultant instruments have a voice that is articulate in its balance, richly colourful, and powerful enough for the most demanding of halls.

Sound Port:

Many players (and makers) view the sole purpose of a sound port as that of a "monitor" for the performer. I think of it a little bit differently. I use a small port on the player's side for two primary reasons: adjusting the frequency of the air cavity and air exchange. Cutting a sound port into a guitar effects the resonant frequency of air cavity. Careful adjustments to the size and position of the port allows me to target a specific pitch and optimize the voice of the instrument. If you consider that the guitar is an incredibly complicated air pump the importance of moving air seems totally reasonable. Without getting too far into the mechanics, imagine trying to run a marathon with your nose plugged or pouring gasoline out of a jerrycan with the vent closed..."glug-glug-glug". Now imagine unplugging your nose during that marathon or opening a vent in that jerrycan... "whoosh". For guitars that "whoosh" is a very good thing.

Low Mass Bridge With Reinforced String Holes:

The bridge of the guitar is the single heaviest "brace" on the top. The acceleration of the bridge is directly related to the production of sound —yet again, more acceleration equates to more sound. Lower mass bridges accelerate more under the oscillatory force of the strings. My bridges are exceptionally low mass and shaped for strength and stiffness. I believe that it is our responsibility to pursue the exploration and development of our instrument. Honouring tradition means respecting what works and correcting what history has told us is flawed. One established "issue in the system" is that over time the string holes in the bridge distort due to the crush of localized loading at the tie block. I install metal bushings in my string holes to -hopefully- ameliorate the issue.