The materials used for an instrument ultimately define its potential. Understanding “what” your tonewood is leads to “how” to use it best.

I believe that exceptional instruments begin with a better understanding of your materials. Antonio de Torres is said to have once explained “...it is the result of the feel of the tips of the thumb and forefinger communicating to my intellect whether the soundboard is properly worked out to correspond with the guitar maker's concept and the sound required of the instrument.”¹ As a fledgling guitar maker I obviously didn’t have that skill yet, so I started measuring. Thankfully there are a number of "modern" methods that allow us to measure the material properties of wood simply and accurately. After years of continued testing for properties like stiffness, damping, velocity of sound, and density I have benefited from a tremendous amount of accumulated data.

I value wholeheartedly and am committed to positive “wood stewardship”. When possible I advocate for the use of domestic tonewood and sustainable materials. I think that wood should be treated as a valued commodity and I contribute to those dedicated to fighting deforestation and the return of biodiversity.

Soundboard:

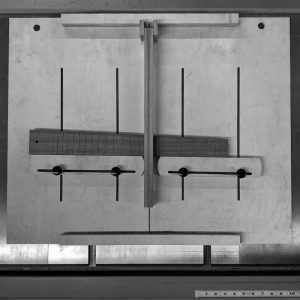

Put quite simply, I am fanatical about my soundboard material. I believe in what matters and that's the intrinsic qualities of each individual piece. I test and examine every potential soundboard to determine its suitability. Most are not. The soundboard is the single greatest element in the production of sound. In the structure that makes up the "top" (i.e. soundboard, bracing, bridge), the soundboard is the primary mass, it's what provides the elemental stiffness to the system, and the speed of it is what determines its potential for transmitting energy. I know I have demanding criteria for my soundboard material and it's part of why I conduct material tests. I don't believe that any one species or "kind" of spruce (or cedar for that matter) is inherently superior to others and nature doesn't subscribe to generalizations. My job is to look at each individual piece and ask myself how I can best use it to achieve the goal.

Back/Sides:

There is a staggering variety of hardwoods suitable for the construction of guitars. I am frequently asked where I “get my wood from” and the answer to that is simple... anywhere I find something suitable. I have scoured lumber yards, imported billets, harvested trees, and experienced some remarkable places in the pursuit of good wood. If the top of the guitar is what determines its voice, then it's the back and sides that colour it. I evaluate my back/side materials (primarily) in terms of damping and velocity of sound. The material properties paired with the aesthetic direction of the instrument determine its suitability towards the goal. I have a wide selection of back and side sets that I have personally selected and seasoned. I believe that wood is a precious resource and that part of our job is to make the best use of it. I have built quite a few multi-wood instruments where the back/sides are created from multiple pieces. It’s not all that uncommon in historical instruments but is a technique that has almost been irresponsibly abandoned by today’s generation. I would much rather use the best wood I can find, even if I need to get “creative”.

Neck:

The structural goal of a neck is stability. The neck must have the requisite stiffness and a superior ability to maintain its original dimensions when subjected to change in temperature and humidity. I reinforce all of my necks with carbon fibre. Mahogany, Spanish cedar, maple, and cherry can be found in quality, but that is by no means an exhaustive list. I select, prepare, and season a variety of suitable material. The ultimate selection is made in consideration of the goals of the instrument.

Fretboard:

Beyond its durability and "traditional" appearance Ebony is a terrible wood for a fretboard... it isn't dimensionally stable and its continued use is contributing the devastation of forests. Regardless of its questionably suitability it is what the current market demands. I am committed to purchasing sustainable ebony, employing other suitable woods, and exploring composite materials.

Bridge:

At the beginning of my career, I built my bridges from the traditional materials. As my thinking about the function of the bridge developed, there was an evolution in my material criteria. At a particular dimension and structure the bridge had to weigh the correct amount. A very small percentage of the conventional “bridge woods” meet that target, so I stopped using them. Black walnut is available domestically, stable, and meets my material criteria. I install metal bushings in the string holes as a preemptive measure against tie block wear.

¹ Romanillos, José L. (1990) [1987]. “Antonio de Torres, Guitar Maker, His Life & Work”. pp. 16–17.